manufacturing

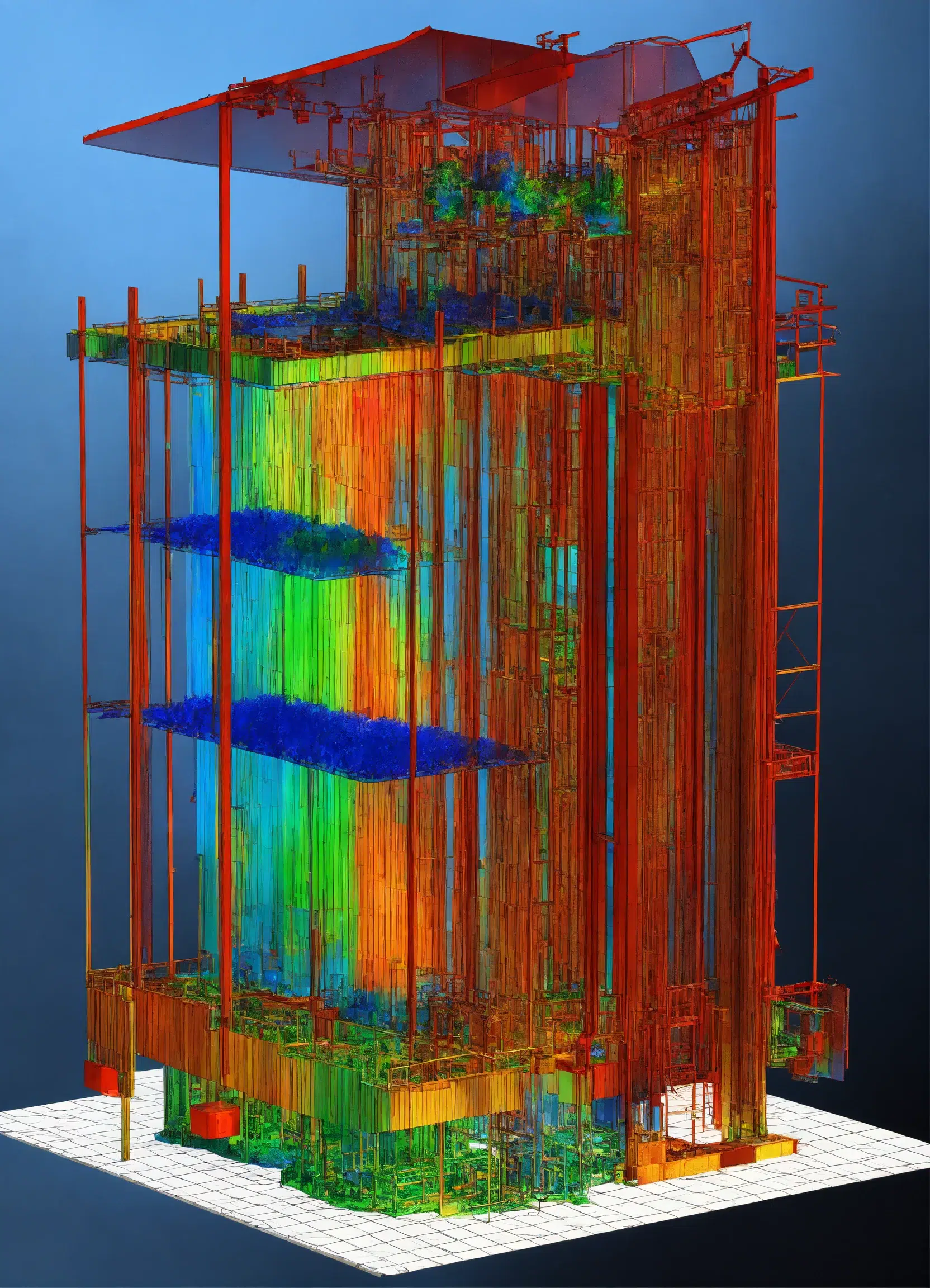

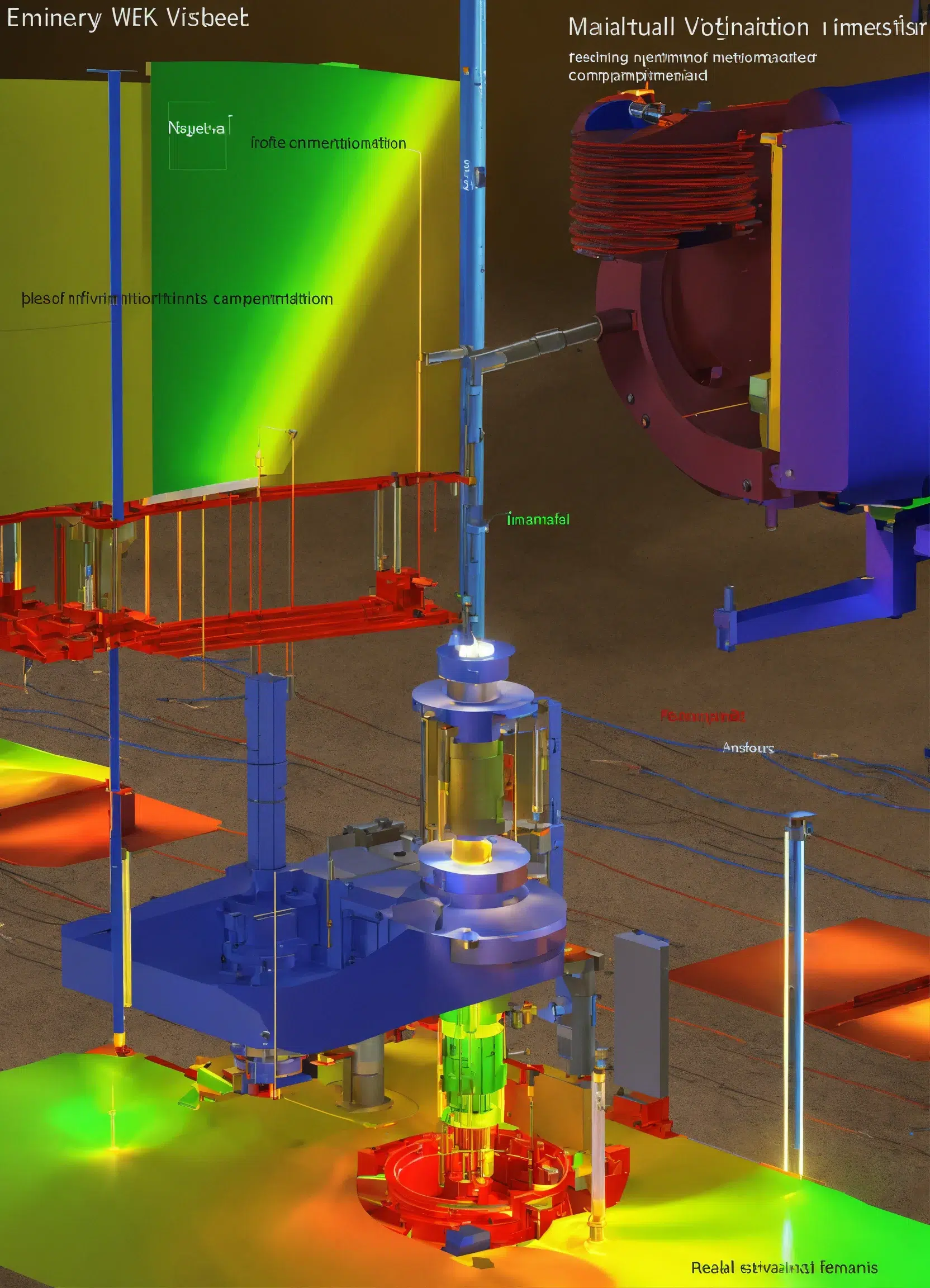

Don Computing excels in addressing a spectrum of complex design challenges in the manufacturing sector, leveraging the power of Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD). Our expertise in thermal stress analysis through FEA is crucial for understanding the effects of heat on materials in processes like welding. We optimize fluid flow in manufacturing systems using CFD, ensuring efficient cooling and heat management. Our vibration analysis via FEA mitigates wear and tear in machinery, enhancing operational longevity.

Our acoustic analysis reduces equipment noise levels, and our material usage optimization minimizes waste and cost, demonstrating our commitment to efficient and sustainable manufacturing solutions.

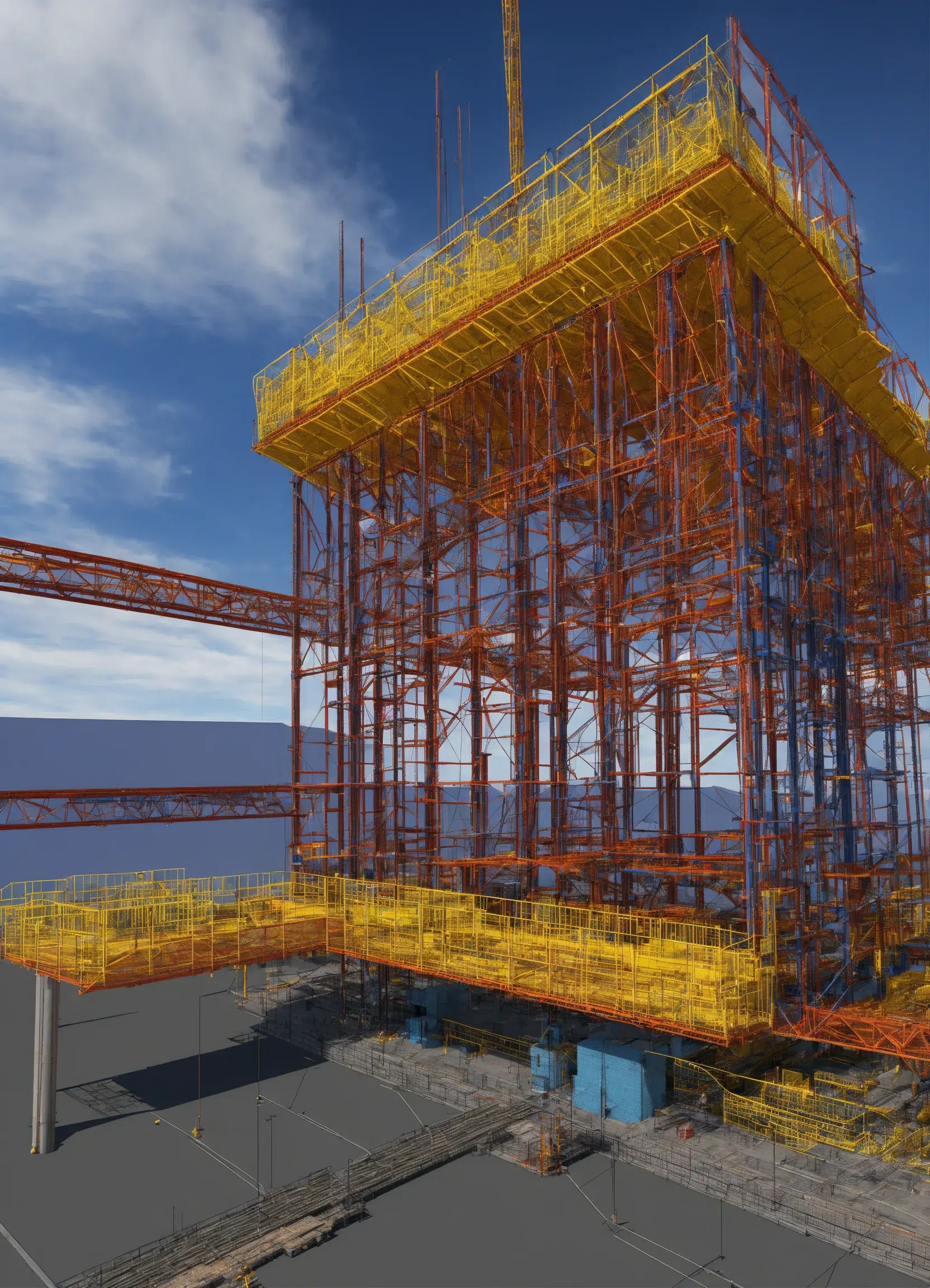

In aerodynamics, our CFD capabilities are instrumental in product design, ensuring aerodynamic efficiency. We ensure structural integrity and safety of components under various stresses through meticulous FEA load testing. Our mold flow analysis via CFD optimizes plastic injection molding, enhancing both quality and manufacturing efficiency. FEA’s fatigue analysis at Don Computing extends product life by predicting and preventing material failure. We also specialize in heat transfer analysis using CFD, crucial for process efficiency and product quality.

Thermal Stress Analysis: FEA is crucial in assessing how thermal stresses affect materials and components during manufacturing processes like welding or casting.

Fluid Flow Optimization: CFD plays a key role in optimizing fluid flow in processes such as cooling systems, ensuring efficient heat dissipation and fluid dynamics.

Vibration Analysis: FEA helps in understanding and mitigating vibration issues in machinery, which can lead to wear and tear or operational inefficiencies.

Aerodynamic Testing: CFD is used to simulate and analyze air flow around objects, essential in designing aerodynamically efficient products.

Structural Integrity and Load Testing: FEA assists in evaluating how structures and components will withstand various loads and stresses, ensuring durability and safety.

Mold Flow Analysis: CFD is applied to analyze and optimize the flow of plastic during injection molding, crucial for product quality and manufacturing efficiency.

Fatigue Analysis: FEA is used to predict and prevent failure due to fatigue in materials subjected to repeated stress cycles, extending product lifespan.

Heat Transfer Analysis: CFD is essential for understanding heat transfer mechanisms in manufacturing processes, crucial for maintaining product quality and process efficiency.